Can robot mowers make a difference at turf roll production sites? To find out, Belrobotics organized a full-scale test in close collaboration with Direct Gazon in the Netherlands. The answer is yes, with a tenfold increase in mowing capacity, faster rooting and superior turf quality. Here’s how it worked.

Growing grass, ensuring its performance and distributing it in rolls. It’s a job that requires a great deal of discipline and rigor. But also perseverance, given the current climatic challenges. Not too much, not too little, turfgrass producers have to ensure adequate watering, combat fungal diseases… and stand out from the competition by offering top-quality products. Belrobotics knows this all too well.

A full-scale test

There are many challenges facing turfgrass growers, but innovation is not always the order of the day in this sector. This led us straight to the idea of testing robot mowers in real-life situations. And that’s exactly what we’ve done in collaboration with Direct Gazon in the Netherlands. Thanks to our Wisenav® GPS-RTK technology, it was easy to set up the robots: no perimeter wires, just the set-up of safety zones on the three test pitches. Not to mention 4G connectivity.

The objectives agreed with the turf producer

- Define the profitability of automated mowing: capacity vs. cost.

- Check the flexibility of the robotized system, taking into account changes in the terrain.

- Identify the impact of robotic mowing compared with traditional mowing.

- Analyze the results for irrigation and fertilization.

Adjusting the cursors for perfect mowing

If mistakes are made in order to learn and not to be repeated, then we have directly detected the challenges of automatic mowing for turf producers. And immediately found solutions. “We looked for the best balance between the desired mowing capacity and the expected quality of cut. The answer lay in optimizing the position of the loading station, using several GPS zones to enable the robot to work even during irrigation, and fine-tuning the mowing directions,” explains Diederick Geerinckx, Sales & Marketing Director at Belrobotics.

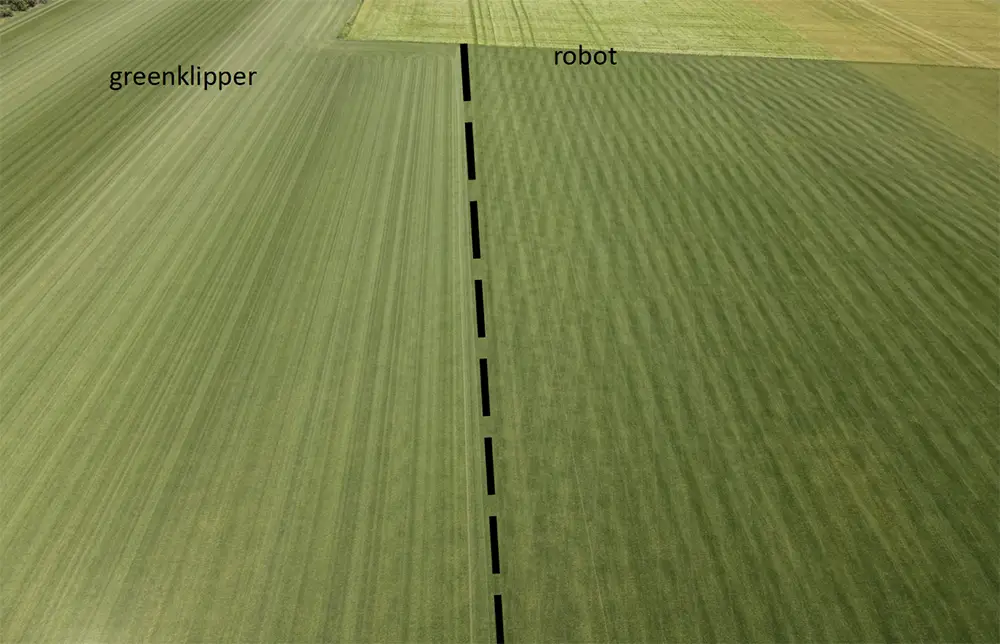

Robot mower vs traditional mower

The test was carried out in parallel with the traditional methods used by growers. We asked Direct Gazon to make two cuts: one after five months and one after eight months. The results? At the end of the first phase, the cuts made by the robot were significantly heavier (1.8 vs 1.1 kg) and root development was much better. The quality of the grass was identical. It wasn’t until the second cut that the characteristics of the grass were comparable to traditional mowing. In other words, the lawn is ready for sale 3 months earlier, thanks to the robot mowers. THAT’S ALL THERE IS TO IT.

5 key results to highlight

- Mowing capacity: Up to 68,000m² mowed once every 2-3 days at 30mm (fast-growing grass). 80% coverage of all standard grass field sizes with just 1 robot.

- Rooting: faster than traditional mowing. Grass is therefore ready for harvest sooner.

- Diseases: Less risk of weeds and mould developing. The low cutting height (30mm), faster root development and light weight of the robot mean it can start mowing earlier.

- Continuous work: GPS is used to define working and prohibited areas. The robot can continue to work while part of the field is being irrigated or during harvesting.

Next steps in the project

“Of course, the results obtained are very encouraging and the next steps will be fine tuning. We are continuing to analyse the impact on fertilisation and irrigation,” says Diederick Geerinckx. From now on, Belrobotics’ technology and expertise will be available to turfgrass producers. The most effective way to optimise production and stand out in a competitive market.

Request your free quote

Robot mowers used

- 2 TM-2050 robots (BM-2050 equivalent)

- GPS-RTK technology and 4G connectivity

- Peripheral wireless installation on 3 sites